Products

pumping systems

Clean Water Pumps

A vast range of potable water pumps and pumping systems for surface and borehole installations are available with materials conforming to WRAC regulations. Please send your requirements through to our Technical Sales Department who will be glad to assist you with your pumping requirements.

Water Pumps are available in varying arrangements from end-suction through horizontal, split-case, high-pressure, vertical, in-line, progressive-cavity, turbine, axial, self-priming, mixed-flow, centrifugal, submersible, well/borehole and on to full bespoke packaged booster-systems.

All our pumps provide outstanding performance in both domestic and commercial environments including potable (drinking quality) water pumping, manufacturing process pump systems and fire-control packages.

DOL or Star Delta operation

Electrical Control Panels

MPD supply and install control panels to suit almost any specification. Our standard range of panels are built for DOL or Star Delta operation. Please forward your project requirements to enable us to offer you a competitive quote.

Control panels provide facilities for pump starting, remote control, dry running / thermal / critical-level protection, timing functions for set-time processes, pressure / temperature / current / flow-rate indication and audible / visual alarms.

Primarily for use in commercial applications such as irrigation systems, lift pump stations, sewage/waste-water treatment works and transfer pump chambers, our panels (whether single or multi-cabinet) provide ease of use and compliance to relevant harmonised standards e.g., CE marking.

Our standard range of panels offer environmental protection to IP55 however we can build to any bespoke requirement. We can accommodate any application and would be pleased to receive your enquiries.

water authority standards

Pressure Booster Sets

MPD supply a range of off the shelf water booster pump sets manufactured to water authority standards, we also manufacture to specific client specifications.

Please contact our Technical Sales Department with the project information to enable us to offer you a competitive quote.

If you have a requirement for higher pressure but variable flow from your water supply and your mains pressure is insufficient, our booster sets will provide the solution; whether you require a fixed-speed unit for a uniform duty or a variable-speed unit for a high demand which varies at certain times (e.g., pubs/hotels or factories).

You will need to include a water storage tank and a pressure vessel in conjunction with the booster pump to aid correct operation and meet current water bylaws.

Reduce energy costs

Pressure Vessels

Pressure vessels are added to a pumped water supply in order to minimise start/stop wear on the pump and reduce energy costs – particularly for very high demand applications with a large variance in that demand.

Vessel size is determined in a fixed speed system by the system pressure and flow rate; under sized vessels will increase running costs and mechanical wear. Variable speed pumped systems generally require a much smaller vessel. We are happy to assist in your selection calculations.

Specialised vessels are available upon request.

-

City skyline

Photo By: John DoeButton

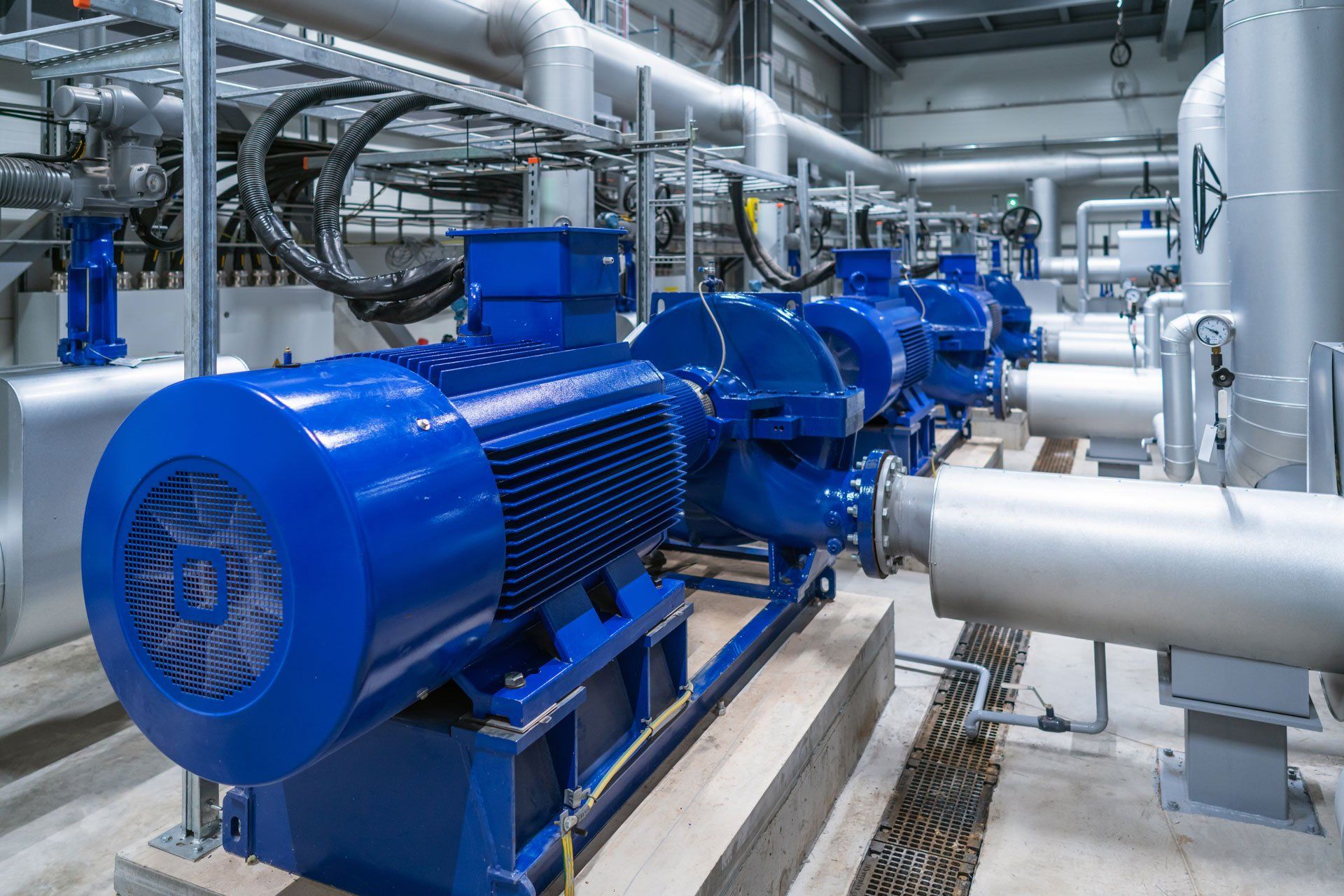

industrial pumping experience

Pumps for Industry

MPD have considerable industrial pumping experience and can provide a solution to your pump problem whether it is for the supply of a new pump, spare part or the repair of an existing unit. Contact our Technical Sales Department or Service Department for more information.

Provide pumping solutions for the movement of fluids from clean water through effluent, sludge, solid waste and drainage to abrasive / viscous / corrosive liquids and acids for virtually any application. Contact our sales team to discuss your requirements.

WATER PUMPS

Sewage & Waste Water Pumps

An important part of MPD’s business is in project work, requiring the complete process of tendering to a client-produced specification, selection of the pumping scheme and commissioning of the final product.

Sewage Packaged Pump Station

If the main sewer is accessible but at a higher level to or is some distance from the site foul drain, then a packaged pump station may be used to pump unsettled sewage directly to the sewer. Whilst single pump units may be acceptable for individual houses, it is recommended that twin pumping systems be used as they provide assistance for redundancy and mechanical failure. For new-build projects your local Council Building Control team will assist in what they deem to be required for non-adoptable pump stations. You will however have to factor in the requirement for 24 hour storage.

Surface Water Packaged Pump Stations

Due to the amount of rainwater that can fall in a short time period, surface water run-off is often the most demanding of all applications, whether hard-standing or roof areas. Careful calculation of the run-off areas is essential when sizing these pump systems, especially taking into account climate change calculations. Flows of up to 100 l/sec are possible with our packages or our contract division can accommodate flows up to 1000 l/sec.

UV systems and filtration

Water Treatment

UV Disinfection

We are competitive for the supply and installation of UV systems and filtration. We are pleased to offer advice to help you with your requirements. Shown opposite is an installation of UV disinfection equipment at Lego Land Windsor.

Ultraviolet disinfection is an extremely cost-efficient means of killing micro-organisms, which can range from bacteria and viruses to algae and protozoa, within a contained environment. UV disinfection is used in air and water purification, sewage treatment, protection of food and beverages and many other disinfection and sterilization applications.

A major advantage of UV treatment is that it is capable of disinfecting water faster than chlorine without the need for large treatment tanks and use of harmful chemicals.

filtering water

Water Filtration

There are numerous ways of filtering water, each with varying degrees of effectiveness, and varying costs dependant on the final quality of the product. The general purpose of filtering water is to improve the water’s hygiene and visual qualities.

A water filter is a device which removes impurities such as Chlorine (and by-products), Fluoride, Pesticides, Fertilizers (such as nitrates), Heavy metals, Petrochemicals, Dioxins, Radioactive Materials (e.g., radium) and Micro-organisms (bacteria/fungi/parasites) from water by means of a fine physical sieve. Filters are used to cleanse water for drinking, aquariums etc. or for industrial processes that require clean water and are available in differing configurations such as Cartridge and Bag, with a wide selection of housings to suit your requirement. Used for removal of harmful substances, or to improve the taste, colour and odour of drinking water. Water filters can be attached directly to a tap, to the water supply before an outlet or at the point of use via a portable unit.

Reverse Osmosis is another form of filtration which cleans to the ionic range of the particle scale. RO systems typically include a number of steps:

A Sediment Filter - to trap particles including rust and calcium carbonate (if necessary, a second sediment filter with smaller pores can be added).

An Activated-Carbon Filter – to trap organic chemicals and chlorine which will attack and degrade reverse osmosis membranes.

A Reverse Osmosis (RO) Filter – which is a thin film composite membrane (if necessary, a second carbon filter to capture those chemicals not removed by the RO membrane) and optionally, an Ultraviolet lamp at point of use (for disinfection of any microbes that may escape filtering by the reverse osmosis membrane).

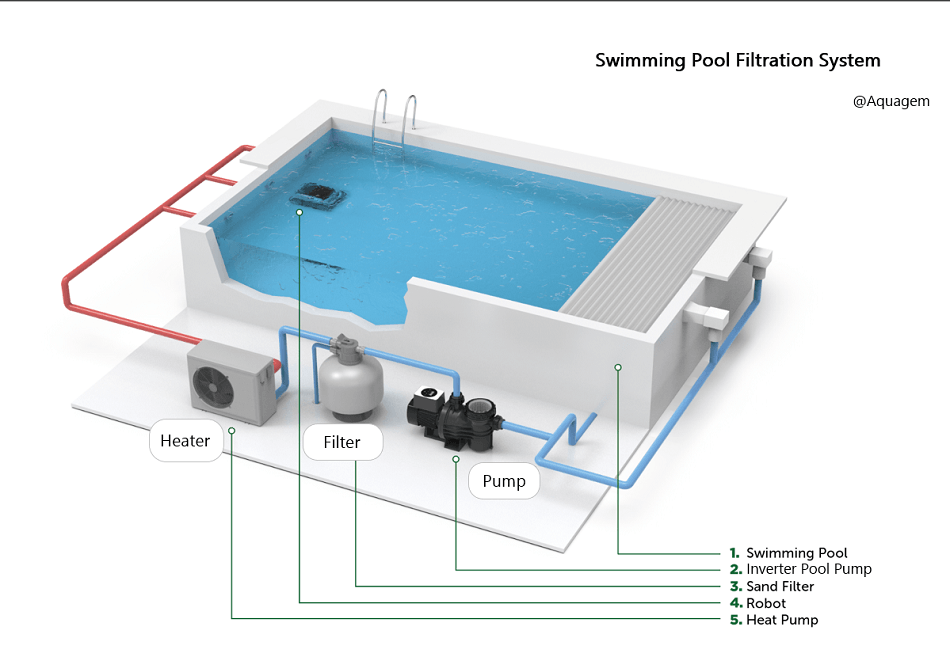

We also supply and install a range of filtration equipment for swimming pools, please contact our sales department for assistance.

water tanks

Water Storage Tanks

Unsurprisingly, water tanks store water, but do so in many guises; from adapted 40’ containers to bespoke, shaped tanks that sit on a booster-set’s frame.

Tanks can be one piece or sectional (largely dependent on their size) and sectional tanks can be internally or externally flanged according to your operational and aesthetic requirements.

domestic and commercial pumps

Swimming Pool Pumps

There are numerous manufacturers in this market, and it is very competitive but with so many things in this world, you get what you pay for. Bear in mind that these pumps generally run 24/7.

We supply a complete range of domestic and commercial swimming pool pumps to suit any application.

water storage tank

Borehole & Well Pumps

Also known as Bore-hole Pumps, this product services the 1% of the population that is still not supplied via the National Water Boards (some 650,000 people!).

Borehole pumps are generally available from 4” to 12” diameter with flow rates up to 900 l/min and discharge pressures to 500m.

Whether you opt for an above ground Jet Pump (for a shallow well) or a Submersible Pump (for a deep well), a water storage tank of some kind may be required.

absorb heat in one place

Heat Pumps

All our surroundings, even a block of ice, has heat. The purpose of a heat pump is to absorb heat in one place where it is plentiful, then to transport and release it in another location where it can be used for space or water heating.

As with many technologies that we use in every-day life, the basic principles of how a heat pump works are simple.

Useful heat can be found in the air outdoors, in the ground, and is present in water, rivers, lakes and the sea. Even on the coldest winter days, sufficient heat is present to warm our homes and offices – what’s more, it is free. All we have to pay for is the machine to recover it and the cost of the energy to run the machine.

prevent seepage AND leaking

Pump Seals

Unless you have installed seal-less hardware, your pumps will be reliant upon seals be they mechanical, lip or gland packed to prevent seepage / leaking / escape of liquids and gases into the environment.

They are available in a vast array of materials such as tungsten carbide, carbon, ceramic, silicon carbide etc. It is important to fit the correct seal for the application ensuring the elastomers are suited to the pumped medium.

CONTACT US today

Get in Touch

Have a question or want to know more about our products and waste pump solutions?

Unit 2, Intercity Industrial Estate, Bath Road, Melksham – SN12 8DE

All Rights Reserved | MPD Pumps LTD